Refrigerated Air Dryers

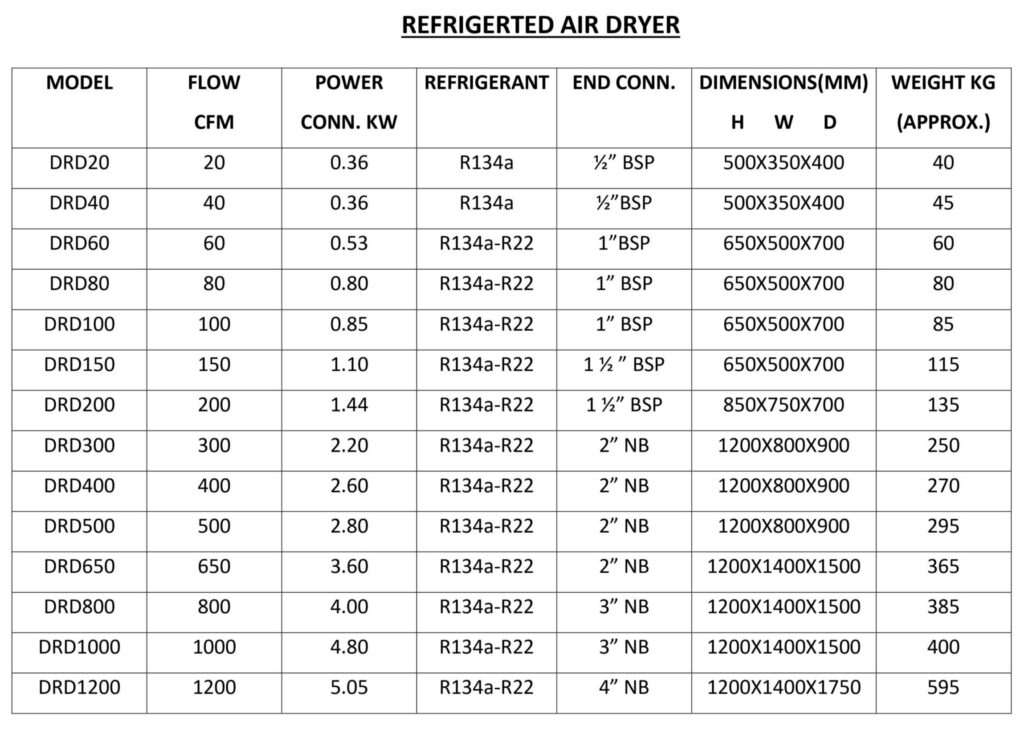

DIMPLE REFRIGERATION TYPE AIR DRYERS 20 CFM TO 1000 CFM

A refrigerated Air dryer is the most commonly used type of compressed air dryer / Gas Dryer for most plant applications for the drying of plant air and other utility gases like Seal gas , hydrogen gas for generator cooling , nitrogen Gas drying etc. Compressed air enters the Air to air heat exchanger where it is pre-cooled by outgoing cold dry air. Pre-cooling makes it possible to use a smaller (More Economical) refrigeration unit. The pre- cooled air enters the Air to Freon Heat Exchanger where it is cooled down to +3C. At this temperature, water condenses into liquid droplets, which are removed from the air steam by a very efficient demister and automatically discharged by a automatic drain value. The cold dry compressed air passes back through the secondary side of air to air heat exchanger where it is reheated by the incoming warm air. Reheating the outgoing compressed air increases the volume of the air enabling it to more work and it also prevents downstream pipe sweating. Heat Exchanger has no extended surface or sharp corners that collect dust, dirt or oil residue. Any dust, dirt oil will be washed from the air system along with the condensed moisture at the De- mister.

- Digital Controller

- Pressure up to 70 kg/cm 2

- Large Condenser for High Ambient Temperature.

- Advanced 3 in 1 Integral Heat Exchanger